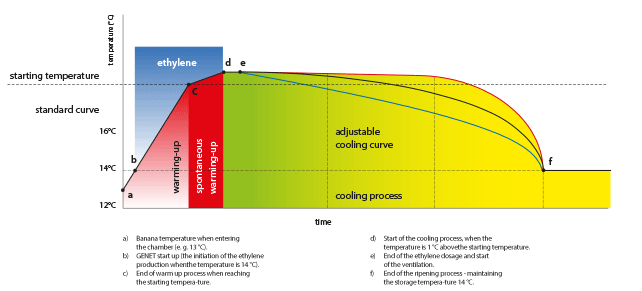

ART is a microprocessor controlled fully automated ripening technology of fruits, especially bananas. In the Ripening Room temperature and ethylene concentration are controlled so that bananas are ripe in an adjustable term and thereafter kept at the optimal warehousing temperature.

As the ethylene source the ethylene generator GENET which is placed inside the ripening box. ASEKO delivers the ripening technology of third generation, fully automated, with the possibility to chose the normal, shortcut or prolonged ripening time.

As ethylene source the portable ethylene generator GENET is delivered.

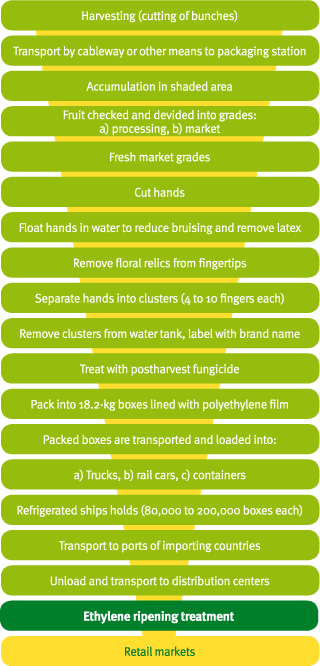

From a botanical point of view a banana plant is a grass, but as tall as 4 meters. The corm of a plant emerges a shoot, and in 1 year the plant flowers. Developing of a bunch takes up to 4 months. It is harvested mature, but not ripen. That is, the fruit is not edible at harvest time: it is very firm, contains latex and the flesh is high in starch. Cut off bunches are then transported from the plantation to the packaging house. The first operation there is inspection and dividing the fruits into processing and market grades. If a bunch is chosen to be marketed, it is cut into separate hands and carefully washed in special pools with additions of fungicides. Clean hands are inspected again and cut into clusters of 4-10 fingers each and labelled with brand name. The last step in the packaging house is packing bananas into character 18 kg boxes and cooling to 14°C. Now bananas are ready for their transoceanic journey. All these operations from a plant to a ready-to-go box should be performed over 48 hours.

HEAD OFFICE

ASEKO, spol. s r.o.

Videnska 340, Vestec, Prague, 252 50, Czech Republic

VAT ID: CZ40766471

+420 603 516 261